B9 Materials

CASTING MATERIALS

Our castable resins print in incredible detail, with a jeweler-approved burnout schedule that produces flawless results in silver, gold, platinum, and more. Coupled with our high-speed Gray resin for showing customers their rings to enable same-day sales and Black resin for mold making, you can create rubber molds and facilitate mass production of your designs.

EMERALD RESIN

Provides clean burnout, enables casting of thicker objects, and prints with readable detail to show the finest features of any design.

Casts into gold, silver, platinum, and more. May be primed or painted. May be used to create RTV or silicone molds.

- Clean burnout

- Readable Detail

- B9 Core Series

B9Creator

YELLOW RESIN

The ultimate casting resin. Ideal for companies looking for the most complete burnout and castability. Our fastest-printing casting resin also leaves no ash.

Casts into gold, silver, platinum, and more. May be primed or painted. May be used to create RTV or silicone molds.

- Premium casting resin

- Leaves no ash

- B9 Core Series

B9Creator

CHERRY RESIN

A castable resin pigmented for thin slicing and sharp details. Slices from 30 μm to 50 μm on the B9Creator.

May be primed and painted. May be used to create vulcanized rubber molds.

- Clean burnout

- Vulcanized molds

- B9Creator

DESIGN MATERIALS

Bring your ideas to life. Our suite of design materials are ideal for high-resolution rapid prototyping and design verification. With smooth surface finish, dimensional accuracy, and precise detail, these resins produce excellent prototypes for iterative product design for and make a great base for parts that will be primed or painted.

GRAY RESIN

Ideal for dimensional accuracy, high-speed prototyping and design verification. Print speeds of 120+ mm per hour.

With ABS-like strength properties, Gray Resin can extend your functional prototyping into production value.

- High-speed prototyping

- Dimensional accuracy

- B9 Core Series

BLACK RESIN

High-strength, fast-curing resin ideal for fine features and detailed parts. May be primed or painted.

Excellent resin for using printed parts to create creating vulcanized, RTV, or silicon molds.

- Vulcanized Mold Making

- High-detail

- B9Creator

B9 Core Series

RED RESIN

A castable resin pigmented for thicker slicing and faster printing. Slices from 70 μm to 200 μm on the B9Creator.

May be primed and painted. Printed parts may be used to create silicon or RTV molds.

- High-speed prototyping

- Castable

- B9Creator

HD SLATE RESIN

Formulated for highly detailed, microscale parts with thin walls and features. With no z-bleed, parts have crisp detail and excellent readability.

Optimized for surface finish. Features as small as 100 μm. Precise detail is great for molding and model making.

- Microscale parts

- 20 μm slice thickness

- B9 Core Series

ENGINEERING MATERIALS

Optimize your manufacturing process with our engineering materials, iterating designs more quickly, assessing form and fit, and bringing better products to market - all while increasing efficiency and adding more profit to your bottom line. Perfect for rapid prototyping and end-use applications, our engineering materials that can withstand the manufacturing environment.

RUGGED - NYLON 6

With low modulus, high impact strength and elongation, and low moisture absorption, Rugged is ideal for snap-fit and wear-resistant parts.

Equivalent to injection-molded nylon, Rugged can replace injection molded components. Well-suited for functional testing and low- to mid-volume production runs.

- Impact resistance

- Flexibility

- B9 Core Series

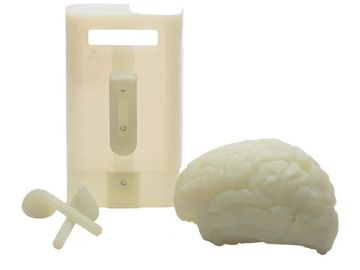

BIOCOMPATIBLE MATERIALS

Ideal for medical manufacturing, clinical, and consumer tech environments, BioRes is ISO 10993 biocompatible for prolonged skin contact of up to 30 days. Durable, impact resistant, and polishable, this material is ideal for rapid prototyping of medical devices to production runs of thousands, surgical tools, anatomical models, medical research, and wearable technology.

WHITE BIORES - MEDICAL/WEARABLE

Ideal for medical manufacturing and consumer tech environments, BioRes is ISO 10993 biocompatible white material.

Formulated for rapid prototyping of medical devices to production runs of thousands, surgical tools, anatomical models, medical research, and wearable technology.

- Smooth Surface, Polishable

- Durable, High-Detail

- B9 Core Med 500

RED BIORES - MEDICAL/WEARABLE

Ideal for medical manufacturing and consumer tech environments, BioRes is ISO 10993 biocompatible red material.

Formulated for rapid prototyping of medical devices to production runs of thousands, surgical tools, anatomical models, medical research, and wearable technology.

- Translucent, Polishable

- Durable, High-Detail

- B9 Core Med 500

Downloads

B9Creations Casting Guide For Jewelers (pdf)

DownloadJAVED SHEIKH TRADING CO. (L.L.C.)

Gold Souq, Al Ras, Deira Dubai, Dubai 20792 AE

Cookie Policy

This website uses cookies. By continuing to use this site, you accept our use of cookies. Privacy Policy

.jpg/:/rs=h:102,cg:true,m/qt=q:100/ll)